Precision Automation And Measurement Solutions

ABOUT US

With 20 years of expertise, Jaten leads in precision automation and measurement solutions.

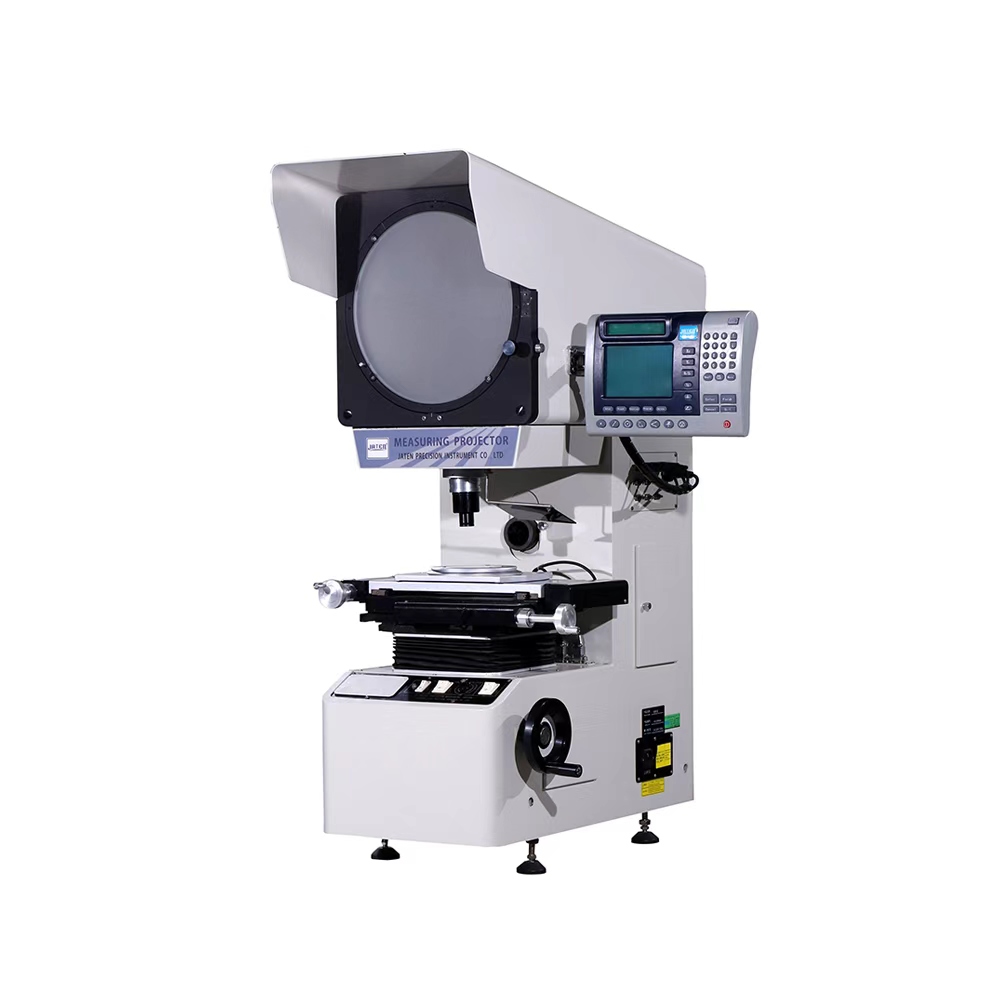

Dongguan Jaten Instrument Co., Ltd., established in 2005, specializes in high-precision vision measuring machines and profile projectors, offering the most comprehensive ranges of models in the industry. With both manual and fully automatic options, as well as optional probes and lasers for basic 3D measurements, our products are widely used in mold manufacturing, injection molding, automotive parts, watch components, and stamping parts industries. Additionally, our equipment supports educational and research applications, providing reliable and efficient dimensional measurement solutions tailored to diverse needs. With nearly two decades of expertise, we are committed to precision, innovation, and customer satisfaction.

PLAN FOR QUALITY

Each new project undergoes a rigorous evaluation process, ensuring the adoption of the most efficient and cost-effective methods that align seamlessly with design requirements. Our goal is not just to meet expectations but to set new standards of quality.

CUT TO SPECIFICATION

Each new project undergoes a rigorous evaluation process, ensuring the adoption of the most efficient and cost-effective methods that align seamlessly with design requirements. Our goal is not just to meet expectations but to set new standards of quality.

SEEK TO IMPROVE

Each new project undergoes a rigorous evaluation process, ensuring the adoption of the most efficient and cost-effective methods that align seamlessly with design requirements. Our goal is not just to meet expectations but to set new standards of quality.

Products

Our products are primarily utilized in the production and manufacturing of new energy and automotive electronics, enabling precise fluid delivery, accurate measurement, and high-precision coating processes.

Solve your industry measurement solutions

We offer a wide range of fluid dispensing products. JATEN automatic dispensing machines are versatile and applicable across various industries. We provide tailored solutions to meet specific requirements, supported by our experienced R&D team

Semiconductor industry

Our fluid dispensing solutions are ideal for the semiconductor industry, ensuring precise and consistent application of materials in critical processes, from wafer bonding to assembly and packaging.

Automotive industry

Our fluid dispensing solutions for the automotive industry ensure accurate adhesive application for components such as sensors, wiring, and seals, enhancing assembly efficiency and product durability

New energy

Our fluid dispensing solutions support the new energy industry by delivering precise application for battery assembly, solar panels, and fuel cell components, driving efficiency and sustainability.

LED

Our fluid dispensing solutions for the LED industry deliver precise application for bonding, sealing, and coating, ensuring optimal performance and production efficiency.

Cosmetics and toiletries

Our fluid dispensing solutions for the cosmetics and toiletries industry provide precise and consistent application of creams, lotions, and other formulations, ensuring high-quality production and packaging efficiency.

At Jaten, it's All About You

Our dedication goes beyond manufacturing; it encapsulates anunwavering commitment to exceptional customer service.Understanding your business, your needs, and your challenges iswhat allows us to not just meet but exceed expectations, fostering partnerships that last.

The team is eager to accelerate your success with cutting-edge solutions.

Contact us today to discover how our expertise can transform your projects and enhance your operational efficiency

Why choose Us

Customer First

We have embraced a 'Customer First'philosophy since day one, which is whywe proudly named ourselves 'SecondIntelligent'

Years of Experience

With 20+ years of experience, we providereliable adhesive glue, material dispens-ing, and potting solutions for various indus-tries

High Quality

Second Intelligent specializes in durableadhesive glue dispensing machines, delivering reliable solutions that build trust andfoster long-term global partnerships.

Direct Manufacturing

Jaten Technology excels in direct manufacturing, with in-house CNC, ensuringprecision for video measuring machinesglue dispensers, and more.

After-sale Service

We have experienced pre-sales andafter-sales teams offering comprehensive support and service Years of Experience

Professional Solutions

We offer complete integrated adhesive automation solutions.

Second Intelligent

Our machines feature easy applicationand installation, designed as modula!units for simple shipping, assembly,use, and service.

Professional Team

In-house software and hardware engineers are at your service.

Discover the latest in our world…

Read the latest blogs about our product catalogs, industry processes and our most successful projects to help make productive business decisions.

Where Do Profile Projector Measurement Errors Come From: Principles and On-Site Factors

In precision manufacturing, profile projectors are widely used for dimensional inspection and contour observation. Compared to contact measurement devices, they are intuitive and flexible. However, users often notice that repeated measurements of the same workpiece can vary, and results may differ between operators.

Work Resumption Announcement

Following the conclusion of the Spring Festival holiday, Dongguan Jiateng Instrumentation Co., Ltd. has officially resumed full production and normal operations as of February 25, 2026. The annual work resumption ceremony was also successfully held.

The True Role of Optical Magnification in Profile Projector Measurements

—Insights from the Optical Principles of JATEN Profile Projectors

The Impact of Optical Magnification on Measurement Uncertainty in Video Measuring Machines Magnification Is Not Just Visual; It’s a Measurement Basis

In optical measuring systems, magnification is often misunderstood as simply “making the image look bigger.” In practice, whether it is a Video Measuring Machine or a visual measuring system, the key factor affecting measurement results is how the optical system maps the physical geometry of a workpiece onto the image sensor for sampling, not the display size. A video measuring machine or any optical measuring device derives measurement capability from proper imaging and sampling conditions, rather than visual appearance. Even if the image is digitally zoomed on the display, measurement uncertainty will not improve if the optical sampling conditions are insufficient. High-end VMMs are therefore designed with optical magnification as a core parameter.